Refrigeration Air Dryer

Our association is broadly known for maintaining the quality in offering Refrigeration Air Dryer.

Heat exchangers are fully encapsulated by PUF insulation to prevent the loss of cooling effect

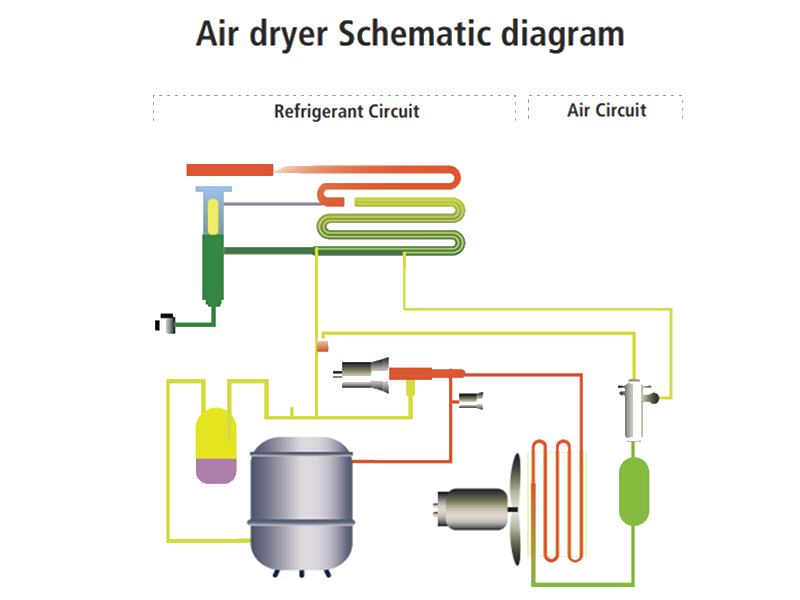

Working Principle

Saturated compressed air enters the Pre-cooler / Re-heater, where it is pre-cooled by exchanging heat with the out going cold air, which reduces head load to evaporator. the inlet air is further cooled in the evaporator to the required dew point. The cold air is then reheated when it passes back through the air-to-air heat exchanger.

A refrigerant compressor and condenser supply low temperature refrigerant to the evaporator. The thermostatic expansion value and the hot gas bypass valve math the operation of the refrigerant system to the compressed air cooling loa. The process cools the air, reducing its capacity to hold water vaper and resultin in moisture condensation.

Air contains contaminats like solid (dust paticles) liquid (moisture) an oil (few traces), which contaminates the compressed air. This untreated wet compressed air enters into the equipments causing failures and affects the production process. Thus, compressed air is to be treated to make it Dry air, free from contaminants.

Comprssed air is the most powerful and useful, portable, easy to use economical source of energy. In manufacturing processes, almost at all stages the compressed air is required and 30% of electical energy is used for conversion of pneumatic energy, the compressed air.

Product Features

Heat Exchanger

- Out evaporator is a CO-AXIAL Heat Exchanger

- It performs as a Precooler and Evaporator

- Our design maximizes exchanger efficiency by using copper tubes in coiled TUBE-IN-TUBE arrangement.

- Heat exchangers are fully encapsulated by PUF insulation to prevent the loss of cooling effect.

Hot Gas Bypass Valve

- It is fitted in between the compressor discharge and the evaporator.

- Evaporator temperature drops below 50ºC

- HGV feeds the hot gas from the compressor outlet to the evaporator.

- Optional to be provided manually and automatically

Thermostatic Controller

- Customized selection according to cooling load and operation condition

- Ensures constant dew poing on verying load conditions

- Sensible to suction pressure

- Sensible to both suction pressure & temperature.

Refrigeration Compressor

- Regged & reliable hermetically sealed Reciprocating/ Scroll compressor

- Suitable for eco friendly gases & Less Noise level

- Low power consumption & Better COP

- Heat exchangers are fully encapsulated by PUF insulation to prevent the loss of cooling effect

Temprature Controller

- Dedicated Programmed micro controller, integrated with temperature controllers and sensors to indicate the dew point, inlet & condensing temperature with following alarms

- On delay time to protect the compressor due to sudden failure