Line Filter

Enhancing Efficiency and Quality

The Role of Line Filters in Compressed Air Processes

Compressed air serves as a versatile and vital utility in various industries, powering pneumatic tools, manufacturing processes, and automation systems. However, ensuring the purity and quality of compressed air is crucial for maintaining operational efficiency and product integrity. In this pursuit, line filters play a pivotal role in optimizing compressed air systems, safeguarding equipment, and upholding product quality standards.

The Significance of Compressed Air in Industrial Processes

Compressed air finds ubiquitous use across a spectrum of industrial applications, including automotive manufacturing, food and beverage production, pharmaceuticals, electronics, and more. It powers pneumatic tools, operates control valves, cleans equipment, and even contributes to packaging and product handling.

However, despite its versatility, the quality of compressed air can impact both operational efficiency and end-product quality. Contaminants present in compressed air, such as moisture, oil, particulates, and airborne pollutants, can compromise machinery, lead to product contamination, or cause malfunction in sensitive instruments.

The Role of Line Filters in Compressed Air Systems

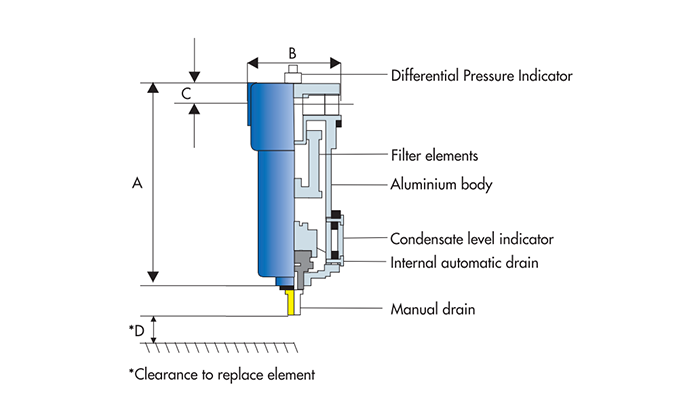

Line filters serve as essential components in compressed air systems, primarily aimed at purifying and conditioning the compressed air before it reaches its intended applications. These filters are strategically placed at various points within the air distribution system to remove impurities and ensure the delivery of clean, dry, and regulated air.

Contaminant Removal

Line filters effectively eliminate contaminants present in compressed air, including oil aerosols, water vapor, dust, and particulates. This purification process prevents damage to pneumatic tools, minimizes wear and tear on machinery, and maintains the integrity of the final product.

Types of Line Filters

In compressed air systems, various types of line filters are employed, including:

Particulate Filters

Designed to remove solid contaminants such as dust, rust, and debris from the air stream, preventing them from damaging downstream equipment or products.

Coalescing Filters

These filters specialize in removing oil aerosols and moisture from compressed air, ensuring a clean and dry air supply vital for sensitive applications and processes.

Activated Carbon Filters

Employed to eliminate odors and remove hydrocarbon vapors or organic compounds, safeguarding against potential contamination in industries like food and beverage or pharmaceuticals.

Enhanced Equipment Longevity

By purifying the compressed air supply, line filters extend the lifespan of pneumatic tools, machinery, and sensitive instruments, reducing maintenance costs and downtime associated with equipment failures.

Quality Assurance

Industries with stringent quality standards, such as food and beverage or pharmaceuticals, rely on line filters to uphold product purity and safety by ensuring the compressed air used in manufacturing processes meets regulatory requirements.

Conclusion

In the realm of compressed air systems, line filters stand as guardians of efficiency, reliability, and product integrity. Their ability to remove contaminants and maintain air quality ensures the smooth operation of machinery, protects sensitive equipment, and upholds stringent quality standards across diverse industrial sectors.

As industries continue to rely on compressed air for various applications, the role of line filters remains paramount in optimizing processes, safeguarding equipment, and assuring the quality of end products. Embracing advanced filtration technologies and tailored filtration solutions, line filters continue to evolve, meeting the dynamic needs of modern industries and contributing to enhanced operational excellence.

© 2021, Airwa. All rights reserved