The Role of Refrigeration Air Dryers

Enhancing Efficiency and Reliability

The Role of Refrigeration Air Dryers

In today’s industrial and commercial settings, compressed air systems play a pivotal role in various applications. They power machinery, operate pneumatic tools, and facilitate countless manufacturing processes. However, ensuring the quality of compressed air is essential, as moisture and impurities can lead to costly equipment damage and operational inefficiencies. This is where refrigeration air dryers step in, providing an effective solution to eliminate moisture and enhance the reliability and efficiency of compressed air systems. In this article, we will explore the key features, benefits, and applications of refrigeration air dryers.

Understanding the Need for Dry Air

Compressed air generated by air compressors contains moisture vapor, which can condense into liquid water when the air cools down. This moisture can wreak havoc on pneumatic equipment and processes, causing corrosion, rust, and operational failures. Additionally, excessive moisture can lead to decreased energy efficiency and increased maintenance costs. To combat these issues, refrigeration air dryers are employed to remove moisture from compressed air effectively.

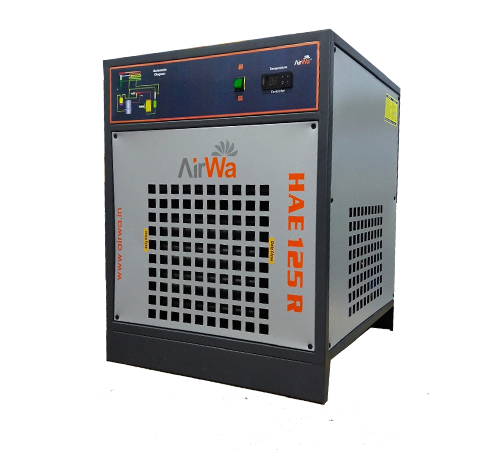

The Role of Refrigeration Air Dryers

Refrigeration air dryers are specialized devices designed to reduce the dew point of compressed air, ensuring that moisture does not condense within pneumatic systems. They achieve this by utilizing a refrigeration cycle similar to that of a household refrigerator.

Key Benefits of Refrigeration Air Dryers

Moisture Removal

The primary function of refrigeration air dryers is the efficient removal of moisture, preventing corrosion and damage to downstream equipment.

Energy Efficiency

These dryers are energy-efficient, as they recover heat from the compressed air, reducing the overall energy consumption of the system.

Enhanced Equipment Life

By maintaining a dry environment, refrigeration air dryers extend the lifespan of pneumatic equipment and reduce maintenance costs.

Improved Product Quality

In industries such as food and beverage, pharmaceuticals, and electronics, dry air is essential to maintain product quality and prevent contamination.

Increased Productivity

Reliable and dry compressed air minimizes downtime and enhances the efficiency of pneumatic tools and machinery.

Applications of Refrigeration Air Dryers

Refrigeration air dryers find applications across a wide range of industries, including:

- Manufacturing : In manufacturing processes, dry air is crucial for maintaining the quality of products and preventing damage to machinery.

- Food and Beverage: The food and beverage industry relies on dry air to ensure the quality and safety of products.

- Pharmaceuticals: Dry air is essential in pharmaceutical manufacturing to prevent contamination and maintain product integrity.

- Automotive: Automotive plants use dry air for painting, welding, and other critical processes.

- Laboratories: Research and testing laboratories depend on dry air for accurate and reliable results.

Conclusion

Refrigeration air dryers are indispensable components in compressed air systems, ensuring that the air remains dry and moisture-free. Their ability to enhance equipment reliability, reduce maintenance costs, and improve productivity makes them essential in various industries. By investing in refrigeration air dryers, businesses can protect their valuable equipment and processes while optimizing their overall operational efficiency.

© 2021, Airwa. All rights reserved